Custom Product Manufacturing in China: A Complete Guide

Custom product manufacturing has come to be a mainstay within the businesses that are out there to distinguish themselves as a part of today’s global competitive market. Firms no longer need to depend on mass-produced items; they are now able to design and manufacture customized products that portray their brand image, deliver specifications, and satisfy the customer’s tastes.

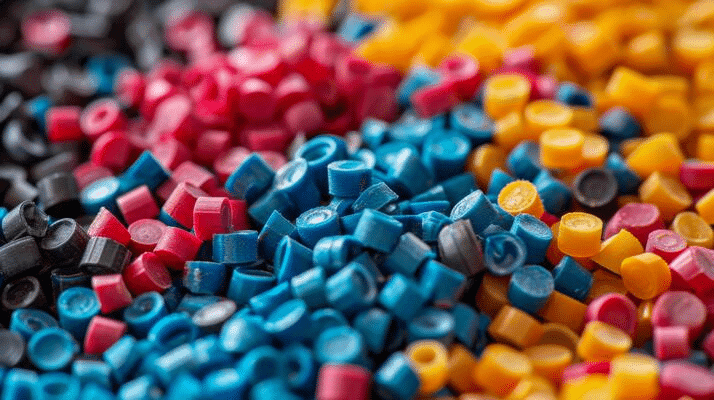

China has become one of the strongest centers of custom product manufacturing, providing cheap products, skilled personnel, and developed technologies in the sphere of manufacturing. Collaboration with qualified manufacturers of custom plastic products enables companies to manufacture quality products within a reasonable time, even when they are dealing with small prototyping or large mass production. The advanced equipment and technologies turn the production of custom plastic products accurate, lasting, and expandable, and allow businesses to ensure the appropriate quality and address the market challenges.

Since the consumer trend toward personalized and innovative products is increasing, the ability to offer custom product manufacturing in the industry is becoming a strategic differentiator. Businesses are capable of designing items that are unique to the brand and that will meet the needs of the customers, in addition to increasing both the recognition of the brand and its competitiveness in the market. Through stringent planning, quality management, and liaison with credible manufacturers, businesses have the ability to realize their concepts to gain success in the developing international market.

This article discusses the Chinese custom manufacturing industry and its advantages, obstacles, and best practices.

What is Custom Product Manufacturing?

Custom Product Manufacturing can be explained as the manufacturing of products that are designed and manufactured according to the unique demands of the client, but not mass-produced standard products. Rather than purchasing ready-made products, a business or an individual collaborates with a manufacturer to develop products of a particular quality/feature, materials, design, dimensions, or operations to suit its requirements.

Important facts regarding the manufacturing of custom products:

- Custom Make: The products are created to standards, including their size, color, materials, or performance.

- Distinct Branding: Companies may add logos, patterns, or packaging to fit their brand type.

- Flexibility: This can be small-scale production (prototypes) or full-scale production of orders.

- Industry Uses: Applied in electronics, plastic merchandise, textiles, promotional merchandise, furniture, and industrial equipment.

- Production Place: China is one of the preferred destinations since it has low manufacturing costs, availability of a qualified workforce, and modern equipment.

In brief, through custom product manufacturing, businesses can transform their creative ideas into actual products that are one hundred percent specific to their needs rather than using off-the-shelf products.

The Emergence of Custom Product Manufacturing in China

The manufacturing industry in China has been changing significantly within a span of a few years. Having been associated with mass manufacturing, the country has also jumped on the bandwagon of the newly developed trend of making custom items, or in other words, custom product manufacturing, which serves the purpose of various businesses in the field of unique or specialized products. Now the companies can cooperate with Chinese manufacturers and can make items under the name of their businesses, which are created according to the requirements of the market.

Custom manufacturing of the products enables companies to be unique, providing personalized solutions suit their brand name. Whether electronics or consumer products, the need to customize products is increasingly becoming faster, and that is why China provides more options to these entrepreneurs and giant companies.

Why Use China to Manufacture Custom Products?

There are a number of reasons why China is the global market leader in terms of the manufacturing of custom products.

1. Cost Efficiency

China has very low investor costs and labour costs compared to most countries in the West. Businesses can synthesize what is known as the concept of a custom-manufactured product by using a Chinese manufacturer and produce a partial cost of the product in comparison to the quality standards.

2. Modern Manufacturing

Modern machinery and technologies that favor the production of custom plastic products, the assembly of electronics, and the unique production of other products are employed in Chinese factories. Such capabilities will allow such elaborate designs of products to be brought to reality effectively.

3. Sus Supplier Base

China boasts a huge number of producers of custom plastic products with the potential to manufacture even the smallest prototype to large quantities of the item. This variety enables firms to obtain a desired production partner that suits their need.

4. Flexible Production

Chinese factories can scale their lines back or forth, delivering 100 units or 100,000 units to meet the supply demand without any compromise to businesses of different scales.

Key Factor To Consider When Selecting a Manufacturer

Even though China presents great opportunities, a proper strategy should be used when choosing the right partner to work with in the area of manufacturing custom products. Some points to take into consideration are as follows:

1. Experience and Expertise

The collaboration with the seasoned manufacturers of custom plastic products would guarantee production of your product at superior parameters. Analyze the portfolio, customer feedback, and past work to get an idea of the expertise of a manufacturer.

2. Quality Control

In “custom-manufactured products,” quality assurance is crucial. Inquire with the prospective manufacturers on quality check steps, certifications, and tests done to avert any expensive errors and retain the good name of your brand.

3. Service & Support

Work with overseas manufacturers can only be done using proper communication. Make sure it is a company that speaks English, with a timeline of their production and good after-sales services. This assists in reducing miscommunications in the course of production.

4. Protection Of Intellectual Property

When a company makes an investment in distinct designs, it is important to have protection of the intellectual property. Cooperate with producers who are knowledgeable about rights to IP, will sign non-disclosure agreements (NDAs) to protect your designs.

Custom Product Manufacturing Process

Knowledge of the workflow can assist the companies in streamlining their “custom product manufacturing” projects. Normally, the process involves:

1. Product Conceptualization

To start the journey, product specifications, materials to be used, and the desired functionality are defined. Proper recording of the design requirements is also necessary to be able to communicate with the manufacturer in an effective manner.

2. Prototype Development

The majority of the projects that involve the manufacture of custom plastic products begin by prototyping. The concept of designing is also created through the production of a sample of the product of the manufacturers to testify on the design and ascertain any possible enhancements to be done before production on a large scale.

3. Material Selection

The success of the products manufactured, taking into account the wishes of the client, depends on the correct selection of materials. Be it durable plastics or metals, or other composites, entrusting them to manufacturers who have a variety of options in terms of materials used will enable you to bring out the best in the end product.

4. Production and assembly

After approval of the prototype, production is taken on a larger scale. Factories also use automated machines and an efficient and skilled workforce to make the production of custom product manufacturing orders in a fast and error-free manner.

5. Quality Inspection

The products go through quality tests before being shipped and ensure that everything is fine according to specifications. This step is particularly important in the case of the so-called manufacturers of custom plastic products, as they have products with complicated designs and fine tolerances.

6. Transport and distribution Shipping and logistics

Lastly, the process of distance trade becomes global by assuring the delivery of your products, with the manufacturers in charge of packaging, shipping, and any documentation required to deliver your products safely and on time.

Benefits of Custom Manufacturing of Plastic Products

Design Flexibility

Design freedom is one of the greatest virtues of custom manufacturing of plastic products. Manufacturers have the freedom to produce products in an unlimited range of shapes, sizes, as well as colors, and even in the use of complex textures or patterns. This enables businesses to realize unique ideas so that once a final product is produced, it is dissimilar to the available products in the market, and it also suits their brand image.

Cost-Effective Production

Other products made of plastic tend to be cheaper to manufacture in comparison to other materials. When the manufacturing process is carried out on a large scale, the per-unit cost is relatively low, hence it is an affordable production process as far as small businesses and large firms are concerned. Moreover, it is much easier to mold and shape plastic, which explains the short manufacturing time and labor expense.

Quality / Durability

Plastic materials of high quality are light and strong, in addition to having good resistance to wear, moisture, and corrosion. This stability makes the custom plastic products very durable and thus able to sustain everyday uses, making them proper in the consumer goods market, industrial goods, and even medical devices.

Brand Customization

The manufacturing of custom plastic products gives establishments an opportunity to incorporate their logos, brand colors, or features in the product. This not only facilitates a stable brand identity but also increases product recognition in the competitive market with others. Customized goods frequently imprint more in the mind of the customers than off-the-shelf goods.

Fast Prototyping & Manufacturing

The other benefit is the possibility of developing prototypes and providing them within a short period before mass production. It makes sure that any design faults or upgrades can be done at a very early phase. After the prototype has been passed, there is an efficient increase in production by the manufacturers, which saves them time and resources.

Cross-industry Fit

The application of custom plastic products cuts across many industries, such as electronics, toys, household products, automotive components, packages, and medical. Plastics apply to virtually everything owing to their wide use and the fact that each product can be tailored to meet the specific requirements.

Eco-Friendly Options

Increased environmental consciousness has caused most manufacturers to now provide recyclable or biodegradable plastics for manufacturing purposes. This enables businesses to produce sustainable products without sacrificing quality or design, and it would attract eco-friendly customers.

Intensity in Mass Production

Most production now is made through modern methods of manufacturing products like injection moulding, where every unit is made with the same level of quality. Businesses are able to count on accurate measurements, exact colors, and all the same features in all of their products, even when they create large orders.

General Problems and their Solutions

Though there are various benefits of custom product manufacturing in China, challenges may arise in the process of business. With knowledge of such challenges and a few actions, it is possible to enjoy an efficient production process. A typical difficulty is the issue of language and communication. Misunderstanding may arise where specifications, time schedules, or even the design features are not communicated. To overcome this, one should seek suppliers that employ English-speaking personnel or employ translators. Errors and misunderstandings can also be minimized by having clear documentation in the form of drawings and prototypes, as well as written instructions.

The other issue is that of quality non-conformity. All manufacturers do not uphold the same standards in production, hence may lead to the manufacture of products that are out of specification. Businesses must sit back and look out carefully before choosing well-experienced custom plastic products manufacturers, verify their certifications, and look to past projects as well as getting product samples before full-scale production is initiated. It is also necessary to introduce a rigid quality control system that would be used during the production process. Project schedules may be affected by shipping and logistics delays, particularly when the products are imported. Partnering with trustworthy shipping companies and planning convoys can be used to reduce the interruptions. Maintaining a close watch on shipments and having effective communications with the logistics suppliers ensures that products are delivered to the destination on a timely basis.

Regulatory compliance is another really important consideration. Various markets are characterized by certain industry, safety and environmental requirements. It is crucial to make sure that the products that are manufactured to order correspond with such regulations before having them shipped out. To avoid rejected goods that cost a fortune and legal problems, it is always better to work with manufacturers who are aware of international practices. Finally, pthethe protectionintellectual property should be put into consideration by businesses that come up with individual designs. The provision of proprietary information to foreign manufacturers is associated with the issue of copying or being used by people who are not supposed to use it. The companies can also reduce this by employing non-disclosure agreements (NDAs) and partnering only with respected organizations where such rights are observed.

Successful Manufacturing Tips for Custom Products

1. Research and Find the Appropriate Manufacturer

The successful manufacturing of custom products highly depends on the choice of the right partner. Quality and experience vary among all custom plastic product manufacturers. Examining portfolios, certifications, and customer reviews will also enable you to select a stable manufacturer that will perfectly meet your needs

2. Order Prototypes and Samples

Prototypes or samples, as a rule, should be sought before switching to mass production. This enables you to experiment with the design, material, and working of custom-made products. The early modifications will lessen the mistakes, and you will have the desired product.

3. Communicate Clarity

The creation of a misunderstanding can be prevented but the use of good communication. Possible visual support in forms of CAD files or photographs, frequent updates, a nd very specific and instructional details make collaboration compliant during the production of custom products. Effective communication makes everyone in line and lowers the possibility of errors.

4. Apply Detailed Contracts

The roles, schedules of production, quality, and protection of property should be mentioned in contracts. Essential terms safeguard both the partners and become a point of reference in case of any problem dealing with the product manufacturing of custom plastic products.

5. Keep track of Production

Errors may take place, even in the case of experienced manufacturers. The early stage can help to solve the issue by conducting periodic checks or performing quality assurance independently. The production needs to be monitored so that all outputs of custom product manufacturing match your quality and design expectations.

Sincere Tech: Your Reliable Partner in making Custom Products

We are the specialists in high-quality industry that provides custom product manufacturing solutions to the unique requirements of our customers in Sincere Tech. Our team of experts has years of experience and works with businesses to design custom-manufactured merchandise that puts your business’s brand identity on display and surpasses the expectations of your customers.

The network of reputable partners who create custom plastic products helps us work on projects of any scope, whether it is a small-sized prototype or a large-scale production. An enhanced plastic product manufacturing process and strict quality control mean that each of our products is rigorously checked and passed according to the most sophisticated standards of precision, durability, and design excellence.

A collaboration with Sincere Tech would result in the establishment of an ally in the emergence of innovative ideas into reality. Our aim is efficiency, consistency, and reliability, as this would enable businesses to advance their brand, minimize expenditures, and remain competitive in the current globalized market. Our mission is your vision, and we are dedicated to giving a world experience in all our products.

Conclusion

In China, there is no better opportunity than the custom product manufacturing that provides a company with the most advantageous offer in terms of quality, price, and product specialization. Through partnership with specialized manufacturers of custom plastic products, companies are able to manufacture custom manufactured products according to the exact specifications without necessarily losing the competition in the global world. Through proper planning, quality assurance, and communication, all companies have the opportunity to tap into the manufacturing skills of China to achieve efficient and reliable production of their distinct products.

By investing in innovation through the manufacturing of custom plastic products, companies can not only optimise operations within the company, but also be able to build a strong brand identity, thus making them stand out in competition. With the ongoing increase in demand for customized products, China is one of the primary destinations for innovative companies that want to have their ideas materialized into market-ready products.

FAQs

1. What is customized product manufacturing?

Custom product manufacturing is the manufacture of goods based on the needs of a client. As opposed to conventional mass production, it enables companies to produce custom-made manufactured goods with their design, choice of materials, and functionality that correspond to the image of their brand and suit their needs.

2. What are the reasons to manufacture custom plastic products in China?

China has cheap solutions, labor, and sophisticated equipment. Alliance with certified custom plastic product manufacturers can help produce any custom plastic product manufacturing order efficiently with high-quality results, both in terms of small-scale prototype orders as well as high-quantity runs.

3. What can I do to have quality custom product manufacturing?

Quality can be guaranteed by collaboration with reliable suppliers, making an order of prototypes, introducing inspections, and having clear communication during the custom product production.

4. Is it possible to make small productions of custom goods?

The production of custom plastic products is flexible and accessible because yes many factories that produce custom-made plastic products will accept even small amounts of orders.

5. What is the time frame of the custom manufacturing process of products?

The duration is variable according to the complexity of the product, material, and size of the order. The manufacturing workflow of a custom product involves prototyping, sign off, manufacture, and quality inspection, wwhichdepending on the product, usually involves a few weeks to up to a few months of the process to total delivery.

Leave a Reply

Want to join the discussion?Feel free to contribute!