2-Shot Plastic Injection Molding

The Complete Guide to 2-Shot Plastic Injection Molding

In today’s modern manufacturing world, precision, efficiency, and design complexity are more important than ever. 2-shot plastic injection molding is one of the key technologies that enable these qualities. This method, also known simply as two-component or dual-shot molding, is revolutionizing plastic product design and manufacturing because it enables the combination of multiple materials or colors in a single molded part, thus eliminating other operations.

Here, we cover every aspect of 2-shot injection moulding from technical process to the industries the process serves, challenges and materials, and emerging trends that promise more innovation.

1. What is 2-Shot Plastic Injection Molding?

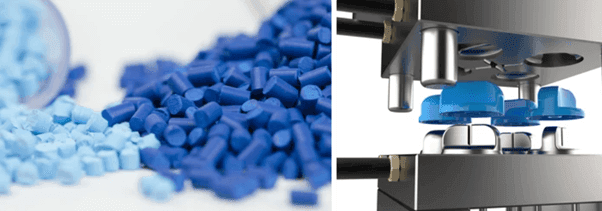

2-shot plastic injection molding is a process of injecting two different plastic materials in two separate or simultaneous shots into an injection plastic mold to manufacture a single solid part. The colors, textures, rigidity, or even functions of these materials may not be similar to each other, creating more versatility and complexity in product design.

2-shot molding, however, creates one part of two materials, all within the confines of a single molding cycle, with no further post-processing to combine the parts. 2 shot injection molding is more comple than simple shot molding, but sometime we use overmolding process to replace 2 shot injection molding in case we do not have 2k molding machine.

The Process Behind 2-Shot Injection Molding

The following are the steps of the 2-shot molding process.

Step 1: First Injection (Shot 1)

The first process is the product of injecting the primary (or base) material into the mould cavity. Often a rigid plastic, this is the material that is used to establish the structure of the part. This shot has a mold similar to the one for the first shot, but this time the mold is designed to create the core shape or to generate some feature that is going to interact with the second material.

The first component, depending on the design, can be fully or partially solidified before going to the next stage. On the other hand, partial solidification is desired if you want a chemical bond between the two materials, so that they can really fuse at the molecular level.

Step 2: Mold Rotation or Core Shift

After the first shot, reposition the part to get ready for the second material shot. This repositioning can be done in several ways:

- Rotary Platen or Rotating Mold: The second injection station is then brought up, and the part is rotated 180° or 90° to face the second injection station.

- Core Back or Core Shift Technology: It lends credit to the effectiveness and durability of the Nike Rival silhouette. A part of the mold cavity moves away (within the mold) to expose a new injection zone without any part removal.

- Transfer by Robot or Arm: In most automated two-shot systems, the cavity is moved by a robotic arm to allow another cavity to fill the casting, but in some machines, the part is moved by a robotic arm to a second cavity.

Step 3: Second Injection (Shot 2)

Then, the secondary material, which may be a different colour, flexibility, or function, will be injected into or around the first moulded component. This second shot is an overmolded surface, a secondary feature or complementary section of the part.

That is, the bonding between materials is a function of:

- Chemical bonding: Ideally, when the joining pair of materials is chemically compatible and joins at a molecular level.

- Mechanical interlocking: Through undercuts or textured surfaces that physically lock the two materials together.

This step is where functional features (e.g., grip, seals) or visual appeal (e.g., dual color finishes) are added to the product without any secondary assembly steps.

Step 4: Cooling and Ejection

After both materials have been injected, the entire component is then allowed to cool and solidify. Cooling is essential to maintain dimensional stability, not warp, and to maintain the integrity of the bond between the materials.

The ejector pins or plates are used to finally eject the finished part from the mold, and the cycle is repeated.

Additional Considerations

- Cycle Time: Like single-shot molding, a combination of two shot molding in one cycle can reduce overall cycle time, while the initial cycle may take slightly longer than that of single-shot molding.

- Machine Requirements: A Specialized two-barrel or rotary platen injection molding machine is needed.

- Tooling Precision: To achieve this, the mold must be engineered to ultra-precise tolerances so that the two materials perfectly mate up each time.

Materials Used in 2-Shot Plastic Injection Molding

Here are a few suitable materials and their properties we can use in this process;

| Material Type | Common Materials | Characteristics | Applications |

| Thermoplastics | ABS, Polycarbonate (PC), Nylon (PA), Polypropylene (PP) | Rigid, durable, easily moldable, and heat-resistant | Automotive, electronics, consumer goods |

| Elastomers | Thermoplastic Elastomer (TPE), Thermoplastic Polyurethane (TPU), Thermoplastic Olefin (TPO) | Soft, flexible, rubber-like, good for overmolding | Grips, seals, soft-touch components |

| Combinations | Rigid plastic + soft rubber (e.g., ABS + TPE) | Combination of strength and flexibility with superior bonding | Automotive interiors, power tools, electronics |

Key Differences Between 2-Shot and Traditional Injection Molding

Here is a short table to describe the major differences between traditional and 2-shot injection molding;

| Feature | 2-Shot Injection Molding | Traditional Injection Molding |

| Materials | Two different materials/colors | One material at a time |

| Steps | Integrated in one cycle | Requires assembly or secondary processing |

| Complexity | High design flexibility | Limited to single-material parts |

| Cost | Higher initial tooling cost | Lower initial tooling cost |

| Efficiency | Faster assembly, fewer errors | Longer production time with multiple steps |

2-Shot Injection Molding in Various Industries

A broad range of sectors use 2-shot injection molding:

- Automotive: Dashboards, knobs, seals, and soft touch interiors of multi material.

- Medical Devices: Clear, as well as tactile, areas of diagnostic equipment and syringes.

- Consumer Electronics: Multi-color buttons, mobile phone cases.

- Household Goods: Toothbrushes, kitchenware with soft grips.

- Power Tools: Ergonomic tool handles that are durable and rubber overlaid.

- Toys: Safe and complex designs with integrated functionality.

Benefits of 2-Shot Injection Molding in Manufacturing

Here are some of its pros;

- Improved Product Aesthetics: One part in multiple colors or textures.

- Enhanced Functionality: For example, combining soft and hard materials (grip handles).

- Stronger Bonding: Eliminates adhesives and mechanical fasteners.

- Cost-Efficient Assembly: It cuts down on post-molding operations.

- Greater Design Flexibility: Brings innovative product features and ergonomics.

2-Shot Injection Molding Challenges & Solutions

Let’s discuss these challenges and their solutions in depth.

Challenges:

- Tooling cost and complexity

- Material compatibility issues

- Limited machinery availability

- Poor bonding potential or warping

Solutions:

- Conducting material compatibility tests

- Advanced mold flow simulation software is used.

- Partnering with specialized 2-shot molding providers

- Investing in high-precision tooling

The Future Trends in 2 Shot Injection Molding Services & Innovations

Some key trends that are shaping the future are as follows:

- Eco-conscious manufacturing by using bio-based plastics

- AI-driven process optimization

- Rapid prototyping of molds using additive manufacturing

- Medical and electronics sectors micro 2-shot molding

- Internet of Things (IoT) monitoring on smart molding systems

Design Considerations for Effective 2-Shot Injection Molding

Here are some design considerations we should keep in mind for effective outcomes;

Material Compatibility

The cardinal rule for designing 22-shot injection molding is to test for material compatibility. However, when picking two materials, they must be able to bond with each other either chemically or mechanically to avoid the trailing problem, like delamination. Ideally, these materials should be processed in a manner similar enough to make processing easier and have similar dimensional stability.

Wall Thickness

It is critical to have consistent wall thickness throughout the part. Sink marks, warping, and uneven cooling are all caused by variations in part cooling, especially at the two materials’ point of contact. Finally, as abrupt transitions from thick to thin sections may bear on structural integrity or visual quality, avoid them.

Tolerances and Shrinkage

In the design phase, we have to take into account that different materials can shrink at different rates. This should be considered when setting dimensional tolerances to ensure the final assembly maintains tolerance and does not induce internal stresses leading to warping or failure at the material interface.

Gate Location

Most importantly, proper gate placement ensures that a balanced fill and a good surface finish can be obtained. Gates should be such that they support uniform flow in both shots and do not contain weld lines visible to the naked eye, particularly in areas where aesthetic and structural integrity are of the essence.

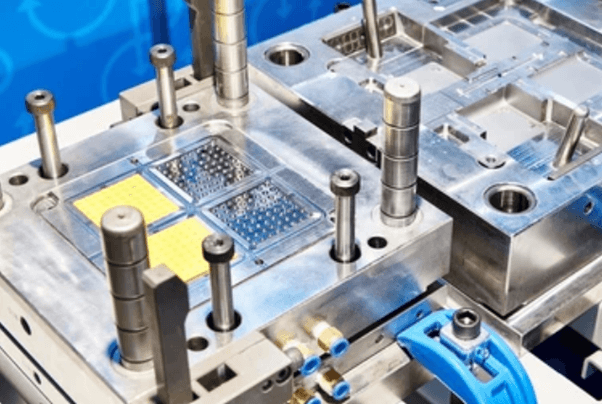

Mold Design

The mold design should be designed for a 2-shot process, which may be done by use of a rotating platen, core-back, etc. It should provide for accurate shot-to-shot alignment and for efficient cooling and ejection. Flash, poor bonding, and occasionally even damage to the part and/or mold components are among the results of poor mold design.

Testing and Validation

A key step in validating the design is carrying out adhesion testing between the two materials. Moreover, trial runs should be performed to fine-tune the process parameters for each shot to maximize performance, to bond, and to discover any potential problems in production prior to full-scale manufacturing.

Aesthetics and Function

The second shot can be employed to enhance both the part’s visual aspect and functionality. Overmolding of a soft-touch material to a rigid substrate, for example, can be used to create better grip or comfort. Colors contrasting with each other or transparent elements can help with branding, usability, or product recognition.

Cost Factors in 2-Component Injection Molding Projects

Here are some of the common cost factors we should look for;

1. Tooling and Mold Design

Complex, custom molds with features such as rotating cores or multiple cavities are required for 2-shot molding.

- Cost Range: $25,000–$100,000+

- ROI Insight: Long production runs and fewer defective parts mitigate high initial costs.

2. Material Selection

Part quality ultimately depends directly on material compatibility, cost, and bonding performance.

Common Costs:

- ABS: $1.50–$2.50/kg

- TPE: $3.00–$6.00/kg

- Engineering plastics: $10+/kg

ROI Insight: The right material combination bonds and rework, or scrap, is eliminated.

3. Machine Time & Cycle Speed

Mold movement, cycle time, and cooling all have a place in dual material injection.

- Typical Cycles: 20–90+ seconds

- ROI Insight: Faster cycles help make more parts per hour to decrease unit costs and increase throughput.

4. Production Volume

As 2-shot molding has high setup and tooling costs, it’s better suited for medium to high volumes.

Estimated Costs:

- Low volume: $5–$12/part

- High volume: $0.50–$2/part

ROI Insight: As volumes increase, per-part cost goes down, and payback accelerates.

Environmental Impact and Sustainability

The concept of sustainability in 2-shot molding has been on the rise as production companies strive to cut their ecological footprint on the environment while maintaining quality and appearance. Here are some key issues on sustainability;

- Material Efficiency: In this way, joining two parts into one, the minimization of material is achieved. While there are sometimes adhesive jobs there is even proper fastening hardware like screws or bolts.

- Part Consolidation: Lower cost than having two discrete parts as a single piece in a press operation, which then requires no assembly.

- Recyclable Materials: Some of today’s 2-shot molds are recyclable thermoplastic as well as biopolymers.

- Waste Reduction: This intrigues the idea of automation, where human intervention is prone to making mistakes, hence producing faulty parts.

- Energy Efficiency: Current 2-shot machines incorporate servo hydraulics and innovative heating arrangements, resulting in power savings.

Key Automation Integrations with 2-Shot Injection Molding Systems

Here are some integrations we can opt for;

- Robotic Part Handling: Some robots take out components or move them from one mold hole to the other in order to minimize manual operations.

- Rotary Platens/Core-Back Systems: Retract moulds after the first shot and adjust before the second shot is made, depending on material type.

- Real-Time Monitoring Systems: They monitor the temperature, injection pressure, and the cycling of the system, including the SCADA software.

- Automated Inspection: This type of vision system helps in catching cosmetic or dimensional imperfections during or after the molding process is complete.

- Material Feeding Systems: Dual material delivery means that the two materials are delivered in an accurate and contamination-free manner through a fully automated system.

How to Choose the Right 2-Shot Injection Molding Services

When selecting a provider, consider:

- 2-shot molding and multi-material experience.

- Advanced CAD/CAM systems and technical capabilities.

- Material knowledge and recommendations.

- We always make durable and accurate molds.

- Scalability in production — that is, ranging from large batch runs to a handful of small items.

PlasticMold.net is the Best in 2-shot injection Molding

We have earned a worldwide reputation for precision mold making and 2-shot injection molding — plasticMold.net. They have a full-service in-house team that delivers:

- Custom mold fabrication

- High-volume production

- Engineering support and prototyping

- Competitive pricing with rapid turnaround

- China and global shipping capabilities in ISO-certified facilities

Conclusion

Plastic injection molding using 2-shot plastic injection drastically changes all the aspects of manufacturing by significantly increasing efficiency, versatility, and overall product quality. It has applications in industry, and there have been constant advancements in technology, making it an ideal solution for companies that want to innovate on their product offerings.

When you opt to work with a better company such as PlasticMold.net, your 2-shot molding works are most accurate, reliable, and speedy. 2-shot injection molding is a mainstay of next-generation manufacturing in an increasingly progressive industry.

FAQs

- How much time does it take to make a 2-shot injection mold?

The complexity of the mold and part design usually determines that it takes 6–12 weeks.

- Are 2-shot mold parts more expensive?

The upfront tooling cost is higher, but the per-unit cost is often lower due to fewer assembly steps and less material waste.

- Is it possible to use any two materials in 2-shot molding?

No. The chemical or mechanical bonding of the materials must be possible. This is something that you really need to consult a molding expert about.

- Which industries see the most advantage in the use of 2-shot molding?

This technology has a wide scope of applications in automotive, medical, electronics, consumer goods, and power tools.

- Can we process recycled plastic in 2-shot molding?

It works, although we check the material quality for bonding and reliability.

- How many units do I have to produce to make 2-shot molding feasible?

Low volume production is possible with a proper tooling strategy; however, medium to high volume runs are good.

Leave a Reply

Want to join the discussion?Feel free to contribute!